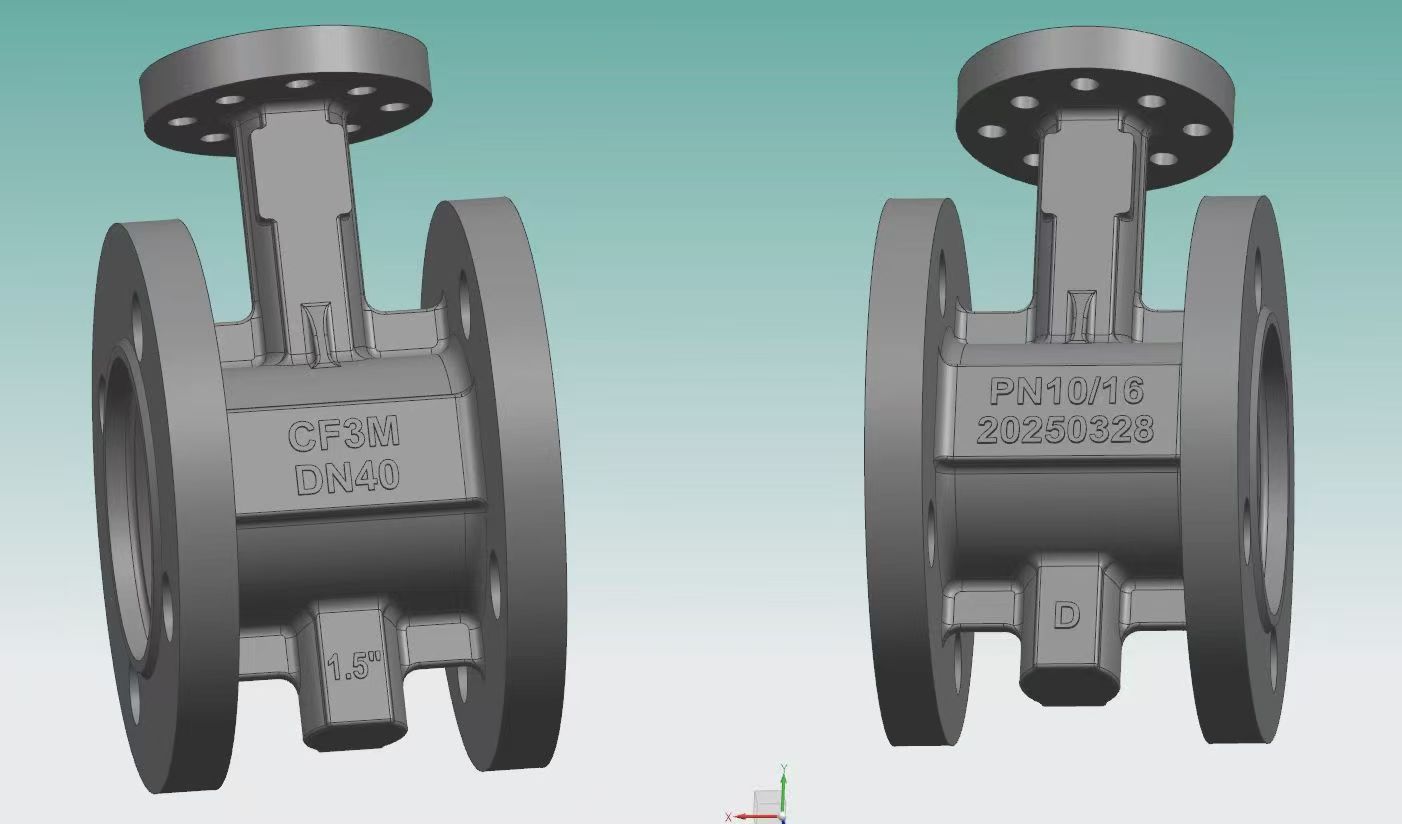

Gate valves are suitable for media such as steam and oil, as well as media containing granular solids and high viscosity, and are suitable for use in venting and low-vacuum systems. Choosing a gate valve requires comprehensive consideration of multiple factors, as detailed below:

1. Identify the application and requirements

Application:

It is important to identify the gate valve's intended use in industrial piping, water conservancy projects, building water supply and drainage, and other areas. Different applications place varying demands on the valve. For example, industrial piping may require higher requirements for the valve's material, pressure, and temperature tolerances, while building water supply and drainage may prioritize cost and ease of operation.

Flow and Pressure Parameters:

Select a gate valve of appropriate specifications based on the flow rate and pressure requirements of the fluid in the piping system. Generally, the nominal diameter of the pipe should match the nominal diameter of the valve to ensure good sealing and flow performance.

2. Understanding Gate Valve Types and Characteristics

Gate valves come in various types, including rising-stem, non-rising-stem, parallel, and wedge-type valves. Each type has its own unique features and advantages:

Rising-stem gate valves: Suitable for applications where visual observation of the valve stem's movement is required, such as in industrial production lines where frequent checks of the valve's open and closed status are required.

Non-rising-stem gate valves: Suitable for applications where space is limited and observation of the valve stem's movement is difficult, such as in underground piping systems or within confined spaces within equipment.

Parallel gate valves: Suitable for low-pressure, large-diameter pipelines. Their gate disc aligns parallel to the valve seat, ensuring a strong seal when closed.

Wedge-type gate valves: Suitable for medium- and high-pressure pipelines. The wedge-shaped gate disc forms an angle with the valve seat, achieving a tighter seal.

3. Selection Based on Media Characteristics

The characteristics of the media are crucial factors in selecting a gate valve. Consider the media's properties (such as corrosiveness, abrasiveness, viscosity, and particle content), temperature, and solid particle size to select the appropriate gate valve material and sealing structure:

Corrosive media: Valves should be made of corrosion-resistant materials, such as stainless steel, duplex stainless steel, Hastelloy, and Monel. For strongly acidic media, stainless steel or special alloys can be used for the valve body, gate, and seat. For alkaline media, a combination of corrosion-resistant materials should also be selected. Also, consider the impact of factors such as the media's concentration and temperature on the material's corrosion resistance and select the appropriate corrosion resistance grade.

High-temperature media: High-temperature-resistant gate valves should be selected, such as those made of special materials like alloy steel or ceramic. Different materials have different temperature resistance ranges. For example, metal seals are suitable for high-temperature applications and can withstand higher temperatures. Rubber seals are generally suitable for ambient temperature applications, with a temperature resistance range typically between -20°C and 120°C. PTFE seals have a wider temperature resistance range, extending from -100°C to 250°C.

Viscous media: For media with high viscosity, the valve's flow capacity and sealing performance should be considered. Generally, a valve with a large flow path and good sealing performance should be selected to ensure smooth flow of the media and an effective seal when closed. For high-viscosity media, gate valves with specialized structures, such as streamlined gate disc designs, can further reduce flow resistance.

Particle-laden media: If the media contains solid particles, a valve with good anti-clogging properties should be selected. For example, a gate valve with a large flow path and a gate disc and seat with high surface hardness can be selected. Alternatively, a filter can be installed before the valve to prevent particles from entering the valve and damaging the sealing surface and gate disc. For media containing particles, valve cleaning and maintenance are also important, and impurities inside the valve must be regularly removed to ensure proper operation.

4. Consider the Operation Method

Based on operational requirements and site conditions, select an appropriate operation method—manual, electric, pneumatic, or hydraulic—while also considering operational convenience and safety:

Manual Operation: For applications with low frequency of operation, low automation requirements, or special circumstances (such as power outages or equipment maintenance) requiring manual operation, a manual actuator can be selected. Manual gate valves offer a simple structure and low cost, but are relatively labor-intensive to operate, making them suitable for small-diameter, low-pressure piping systems.

Electric Operation: For applications requiring rapid opening and closing and automated control, an electric actuator can be selected. Electric gate valves are convenient to operate and can be remotely controlled, but the type and stability of the power supply, as well as whether the power of the electric actuator can meet the valve's opening and closing requirements, should be considered. Electric gate valves are suitable for applications with large diameters, high pressures, frequent operation, or remote control. Pneumatic Operation: Pneumatic gate valves use compressed air as their power source, offering advantages such as fast actuation and easy operation. They are suitable for hazardous locations such as those with flammable, explosive, toxic, or hazardous materials. When selecting a pneumatic actuator, ensure that the air source pressure and flow rate meet the requirements.

Hydraulic Operation: Hydraulic gate valves are suitable for applications requiring high actuation force and high-precision control. However, the hydraulic system has high reliability and maintenance requirements, and regular inspection of the hydraulic oil quality and pressure is necessary.

5. Follow Standards and Specifications

When selecting and designing gate valves, adhere to relevant national standards and specifications to ensure their safety and reliability. For example, according to the recommended national standard "GB/T 32808 - 2016 Valve Model Designation Method," gate valve model designations include information such as valve type, actuation method, connection type, structural type, sealing surface material, pressure rating, and valve body material. Different manufacturers may have specific model designation methods, and the specific meanings may vary. Consult the manufacturer's product catalog or consult a professional if necessary. VI. Other Factors to Consider

Installation Location: Choose the correct valve installation location for easy operation and maintenance, while leaving ample space for necessary adjustments and repairs. For example, for applications requiring frequent disassembly or overhaul, choose a gate valve design that is easy to install and maintain, such as a rising-stem gate valve or one with a bracket.

Budget Considerations: When selecting a gate valve, in addition to considering performance parameters, consider cost-effectiveness, including purchase price, shipping costs, installation costs, and maintenance costs. When choosing a cost-effective gate valve, consider quality, performance, and price comprehensively, avoiding the pursuit of low price while ignoring product quality and performance.